In today’s fast-paced and streamlined production environments, accurate identification is required by some applications. Many O-Rings appear visually identical, but various applications may require certain identifications in:

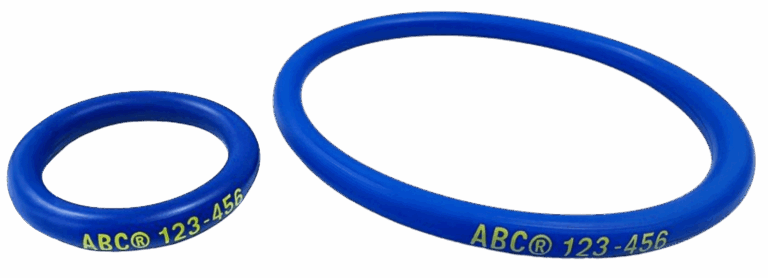

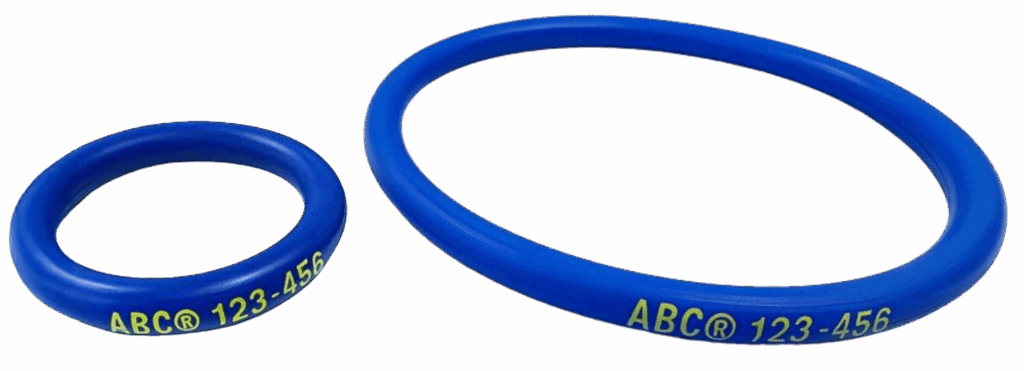

Permanent, high-contrast markings could make it easy to distinguish the right part at the right time, reducing errors and improving production efficiency.

Beyond recognition, proper marking is essential for full traceability. At Precix, each part we produce can be traced back to its production batch, material formulation, and manufacturing location. This level of transparency protects supply chains, supports compliance with industry standards, and provides a layer of protection, specifically aftermarket products being sold in domestic and foreign markets.

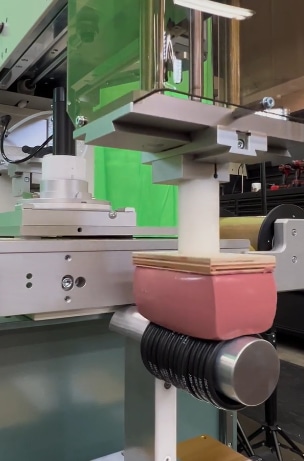

To keep up with our top-of-the-line manufacturing pace, we provide top-notch marking solutions. We use micro pad printing to clearly print part information onto an O-Ring using permanent ink.

Built-in software enables intuitive control and monitoring of ink viscosity settings, allows us to best suit the material, application, and durability requirements of each seal. We work closely with customers to integrate critical information into each marking, ensuring legibility and consistency across high-volume production.

| Printing Capacity | Up to 2,000/ hour |

| Printing Force | 420 N Max |

| Plate Sizes with Ink Cup | 130 x 250 mm |

Like our products, our markings are fully customizable to meet your standards. Our team is ready to help you make your mark!

Please click here to get in touch with a Precix expert!