Enhance assembly efficiency, sealing performance, and cost-effectiveness in your O-ring and seal assembly process with proprietary Precix Lubrication!

The friction characteristics of rubber parts can result from various factors, including the nature features of elastomers, the additions in rubber compounds, the surface finish of the molds, or post-processing techniques applied to rubber during manufacture.

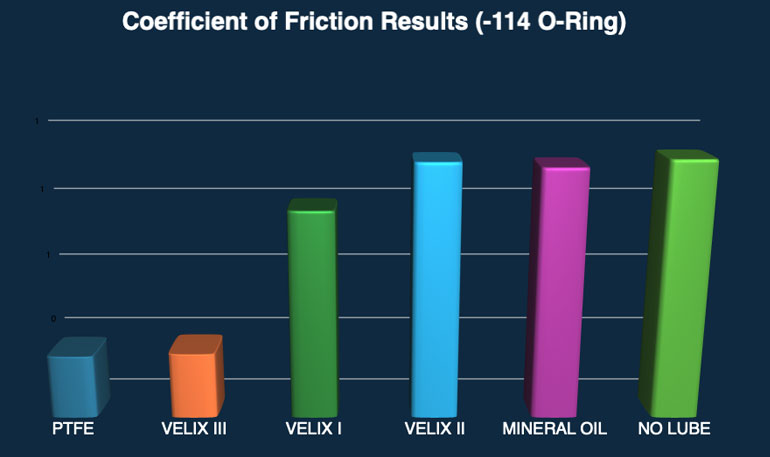

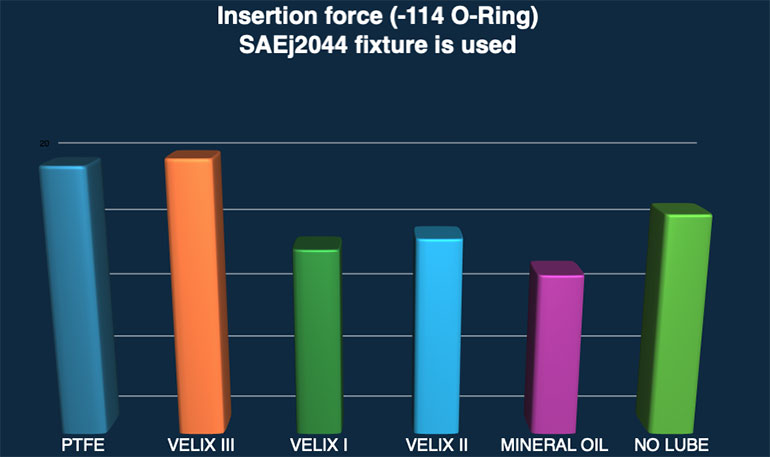

Precix has developed a full range of washes, dry lubes, and coatings to expedite your O-ring/Seal assembly time while addressing your need to remain cost-competitive. The following graphs illustrate the insertion force and coefficient of friction data with Precix O-rings treated with different washes/assembly aides.

As depicted, the proprietary Precix Velix® I & II washes provide the user with the best of both worlds: low insertion force and coefficient of friction for ease of assembly without the mess and expense of mineral oil and/or PTFE coating. Velix® I and II are ultra-low-cost coating options that will enhance your assembly speed while addressing your need for cost control/reduction.

If the ultimate in slipperiness is required, consider our Velix® III option, which boasts a coefficient of friction value similar to PTFE without the associated cracking, flaking, and mess. Velix® III is a permanent clear coating that is perfect for applications where frequent opening/closing is the norm, such as oil caps and gas cap seals.

All Velix® treatments are non-flaking, environmentally friendly treatments applied during the washing of the product.

MSDS and other technical information are available directly from Precix Engineering personnel.